Digital Construction Site: Innovations at digitalBAU 2024

Construction robots, artificial intelligence, BIM and blockchain: the digital construction site offers unimagined opportunities, counteracts the shortage of skilled workers and makes companies fit for the future.

As the leading trade fair for digital solutions in the construction industry, digitalBAU addresses all aspects of modern construction and the digital construction site – from planning, construction and operation to management, conversion, demolition and recycling. Digitization of the construction industry is seen as the key to climate-friendly construction and is therefore part of Germany’s digital strategy. At digitalBAU, you can find out where the industry stands today, which digital methods are already being used and what potential innovative construction site software, artificial intelligence, big data and blockchain offer in construction. The future of construction has begun – be part of it!

The future is digital: construction sites in transition

Digitization has revolutionized the way we live and work. Smartphones and tablets have found their way into our everyday lives and rapid access to information via digital media has changed the way we communicate forever. In virtually all sectors of the economy, the digital transformation has produced new products and services in recent years. Digitization has also found its way into the construction industry: Houses from the 3D printer, robotics, artificial intelligence (AI) and big data are no longer future scenarios – but they are also not yet part of our everyday life. The rapid pace of change offers construction companies previously unknown opportunities.

Digitization in the construction industry has some catching up to do

Digitization has been relatively slow to be applied in the construction sector. This has mainly to do with the specific requirements of building. Architecture is a discipline in which creativity and individual design are culturally embedded. Admittedly, there have always been innovative ideas that have led to more efficient processes, for example in modular construction and serial building. Nevertheless, construction remains to a large extent a complex interplay of different disciplines with many players.

The high level of fragmentation in the construction industry in Germany has also stood in the way of digitization in the past. In 2022, the share of companies with fewer than 20 employees in the main construction trades was 88% (source). This industry structure is in contrast to the manufacturing industry, which has been optimized on a large scale for serial production.

But to remain competitive, companies in the construction industry also need to adapt their systems and processes to the ongoing changes. The market now offers numerous solutions for the digital construction site. New technological developments are constantly being added, which will also be in focus at digitalBAU 2024.

digitalBAU visitor information

The digital transformation in the construction industry knows no standstill. Stay up to date by subscribing to our visitor information.

Digital transformation as an opportunity

Digitization is challenging the construction industry, but at the same time it brings with it many new opportunities. Companies that embrace change remain competitive and save costs. On a digital construction site, many activities can be automated, made simpler and more efficient and be of a higher quality than before. From digital measurements and construction project management software to mobile apps for work preparation, monitoring, communication and data exchange – with digital tools, all companies can increase their efficiency, minimize sources of error and thus reduce costs.

In addition, digitization in the construction industry is a possible solution strategy to counteract the shortage of skilled workers. According to a 2021 survey of 1,900 construction companies in Europe, the US and China, 44% of companies have difficulty finding suitable skilled workers (source). One way to mitigate this shortcoming is to automate standard processes on the digital construction site. Robots can also increasingly take over construction tasks and help fill staffing gaps.

The digital construction site is attractive for young employees

One of the reasons for the dramatic shortage of workers is the lack of young professionals in many trades. Automation technologies and digital construction site management can help make construction professions more attractive to young people. After all, “Generation Z”, which is now in the starting blocks of professional life, is not only much more adept at using digital technology. For many, the ability to use digital tools is in fact an essential criterion when choosing their training or workplace.

The issue of workplace safety is also becoming increasingly relevant in the choice of occupation: around 100,000 workplace accidents occur every year on German construction sites (source). Automation systems, optimized logistics processes and robotics increase safety on the digital construction site and make the industry more attractive for job seekers. For example, construction robots can move large and heavy loads or be used in hazardous areas.

Smart technologies on the digital construction site

Modern robots are capable of performing complex activities independently, controlling them and correcting them if necessary. The use of robots on the digital construction site therefore offers enormous potential for increasing productivity. Today, a wide variety of tasks can be accomplished with the help of robotics: prefabrication of construction elements, creation of modular houses, robot-assisted welding or robot-based 3D printing are just some of the examples that are already being used on large construction sites.

Robotics and artificial intelligence (AI) are associated. AI offers enormous potential for digitizing the construction industry. From automated planning tools to quality assurance to work safety on construction sites, AI can help reduce sources of error and make projects more efficient.

AI reduces dangers

On the digital construction site, artificial intelligence can also be used to increase safety. Sensors for object detection can identify danger zones, such as incorrectly erected scaffolding. Surveying at risky locations or warning of imminent collisions with vehicles or machines are further examples. 3D scanning reduces the need for manual inspections and increases the accuracy of the captured data.

AI systems are also proving their worth in building operation. In heating and cooling systems, for example, they learn independently from user behavior or react flexibly to environmental influences.

In the future, construction companies will also benefit from AI outside the digital construction site: in the search for skilled workers, in the recording of working hours, or in payroll management. Last but not least, in addition to the aspects of productivity and efficiency, experts also see great potential in using AI to increase the sustainability of construction projects.

AI can also be used to analyze a virtual image of the structure – the digital twin. Potential problems or planning errors can thus be identified at an early stage and expensive rework avoided.

BIM and digital twins

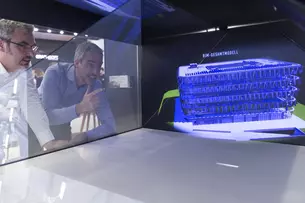

BIM (Building Information Modeling) and digital twins open up useful new opportunities on the digital construction site. BIM allows virtual images of a building project to be created in the context of its surroundings. Digital twins are based on BIM and represent the built reality supplemented with current information. A digital twin thus allows the construction process to be viewed as an entire system, with information density and depth far exceeding that of a classic 3D model.

For this purpose, digital twins are continuously supplemented with real-time information via sensors and drones to show the current status of the construction project. The data from this digital image provides valuable insights into the project – and not only on the digital construction site: digital twins enable better decision-making both during planning and in operation, and also with regard to the separation and recycling of raw materials by type when the structure is demolished. The possibilities are almost endless: optimized designs, low energy consumption, reduction of operating costs and much more besides.

Especially in complex construction tasks, digital twins offer enormous advantages for everyone involved in a project. The better insight and extensive information provided by the digital model is what makes the comprehensive view of the entire life cycle possible in the first place. The high degree of digitization offers the construction industry the perfect parameters for sustainable and energy-efficient construction methods that take into account the entire life cycle of the building.

Blockchain on the digital construction site

In the course of digitization in the construction industry, more and more companies are also discovering blockchain technology. Blockchain offers transparent and secure options for contracts and transactions in the construction industry. For example, data on the documentation of materials used, CO2 costs and any compensation measures can be stored in a tamper-proof manner.

Buildings documented on the blockchain have also proven attractive to investors. In the future, cloud storage in particular will increasingly work with blockchains. Wherever verification, encryption and transparency play an important role, blockchain solutions are the answer.

Big data in construction as a competitive advantage

Digital site documentation and planning, BIM, digital twins and the many other digitized processes in construction naturally produce a large amount of data. The diverse information from construction plans, weather data, ERP systems, sensors, drones, etc. has to be collected and analyzed so that the findings can be used.

However, big data, in other words, the quantity and variety of data on digital construction sites, is challenging for many. Companies that recognize and know how to leverage the value of their data will be able to identify potential for growth, optimize their processes and thus achieve better results in the long term.

Digitization of the construction industry: the future of construction is now

In the construction industry, digitization can make a significant contribution to getting companies through challenging times between economic uncertainty and a shortage of skilled workers. Thanks to digital planning, structures can be optimized and energy consumption and use of raw materials can be minimized, costs can be reduced, and much more besides. The use of innovative technologies on the digital construction site, such as prefabrication or robotics, can help increase quality and efficiency.

The digital transformation is changing design and construction and posing major challenges for the construction industry. At the digitalBAU 2024 trade fair, one of the most important industry events, the “digital construction site” is therefore one of the leading topics. The latest developments and technologies that are shaping the future of construction are presented here. In order to implement digitization in companies in the construction industry in the long term, it is necessary for all those involved to exchange ideas and transfer expertise. digitalBAU offers a platform for this exchange, for information, discussion and innovation.

Other key topics at digitalBAU

Connectivity

Smart City

Circular construction